贵阳Pinggui Jianan Machinery 6-S Series Shaker Instruction Manual s

Product Name: 贵阳Pinggui Jianan Machinery 6-S Series Shaker Instruction Manual s

Category:贵阳Sorting Shaker

Product Overview:

I. Overview

6-S Shaking Table belongs to gravity separation equipment, which is developed from plane chute.It is widely used in the re-election production process for its wide particle size, high sorting efficiency, intuitive working condition and easy operation and management.

6-S shaking table is mainly used for separating gold, tungsten, tantalum, iron, manganese, chromium, titanium, bismuth, lead and other non-ferrous, ferrous and rare precious metal minerals, and can also be used to sort other materials with sufficient specific gravity difference and suitable particle size composition.The use of shaking table beneficiation is stable and reliable, the distribution of ore zone is clear, and can get the final concentrate and discard the tailings.

II. Working Principle

Shaking table sorting is in the bed of longitudinal reciprocating motion and transverse water flow to achieve the role of the water flow transversely across a bed when the formation of water vortex in the grooves, water vortex and longitudinal movement of the bed of the joint role of the mineral sand layer loose and according to the specific gravity of the layering, specific gravity of the ore particles, along the surface of the bed moving at different speeds by the transverse water flow flushing effect is also different, and ultimately the formation of the specific gravity of different ore belt distribution discharge, to achieve the purpose of sorting.The purpose of sorting is achieved.

Structure of shaking table

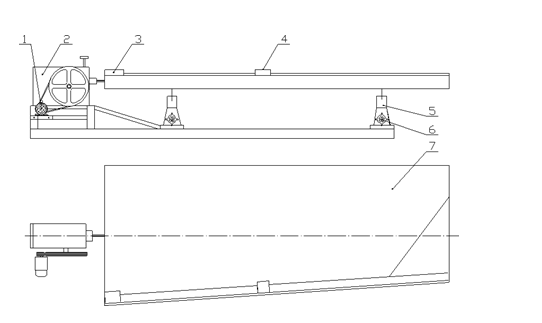

6-S shaking table consists of three parts: bed head (transmission mechanism), bed surface and bed foot (slope adjustment mechanism), as shown in Fig. 1.

1. bed head (transmission mechanism)

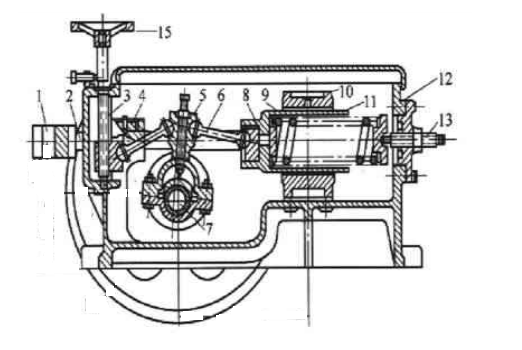

Shaking bed transmission mechanism adopts eccentric elbow plate type, connected with bed surface through linkage seat, so that the bed surface makes asymmetric movement along the longitudinal direction.

When rotating the stroke adjusting handwheel clockwise, the adjusting slider moves upward and the angle between the two elbow plates increases, thus the stroke decreases, on the contrary, rotating the adjusting handwheel counterclockwise increases the stroke.

Figure 1: 6-S shaking table structure

1. motor 2. bed head (drive mechanism) 3. feeder tank 4. wash water tank

5. bed foot (slope adjustment mechanism) 6. slope adjustment handwheel 7. bed surface

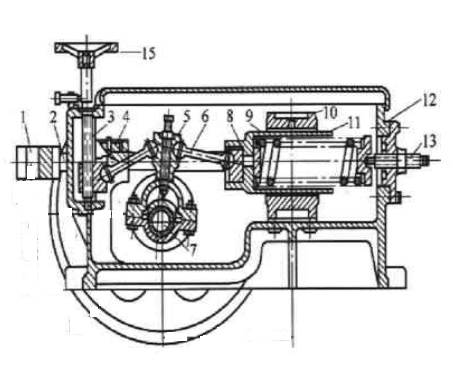

Fig. 2: 6-S Rocker Head Structure

1.Linkage seat 2.Reciprocating lever 3.Stroke adjusting screw 4.Movable elbow plate seat 5.Rocker bar

6. elbow plate 7. eccentric shaft 8. fixed elbow plate 9. spring 10. tailstock 11. tailstock

12. case 13. spring loaded bolt 14. large pulley 15. stroke adjustment handwheel

After adjusting the stroke, the spring adjusting bolts at the back of the transmission box must be adjusted accordingly so that the spring can be properly loosened and tightened to avoid damaging the parts due to over-loosening or over-tightening of the spring.

2. Slope adjustment mechanism

The slope adjusting mechanism of the shaking machine is composed of shaking support, adjusting seat, saddle seat and adjusting screw, etc. When rotating the adjusting handwheel, it will be adjusted by the adjusting screw. When rotating the adjusting handwheel, the adjusting seat rotates on the saddle seat through the screw, so as to change the lateral inclination of the bed surface.

The lateral inclination angle of the bed surface is changed.Clockwise rotation of the handwheel increases the tilt angle, and counterclockwise rotation of the handwheel decreases the tilt angle.

3. Bed surface

The bed surface of shaking table is in the shape of right-angle trapezium, generally made of wood or glass fiber reinforced plastic wrapped with steel skeleton, the working surface is carved groove moulding for special wear-resistant layer, and the groove is divided into straight and waveform (single wave and double wave), according to the different grain size of the minerals, there are divided into coarse sand bed, medium sand bed, fine sand bed and fine mud bed.

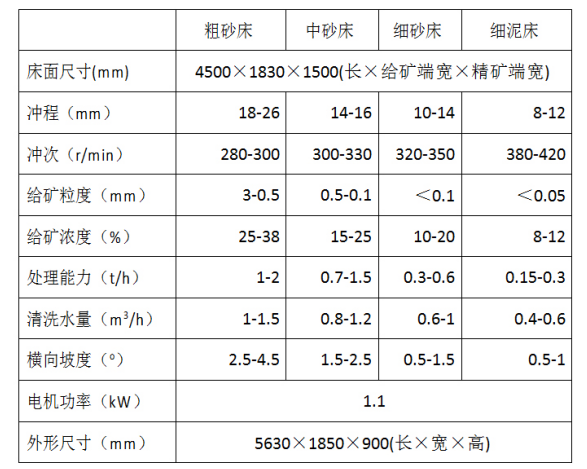

IV. Technical Parameters

五、 安装

设备须安装在水平混凝土基础上。

1. 安装槽钢支架于基础上;

2. 安装传动机构和条坡机构,调坡手轮设置在床面砂(水)槽方向, 校正两个调坡机构回转中心连线与床头中心线重合。

3. 将床面平稳放置在摇板上,校正床面与摇板的接触位置准确后紧 固摇动盒的固定螺栓。

4. 连接床面与床头的联动螺栓,转动大皮带轮使床面纵向运动,观察并调整联动螺栓使四个摇板的前后摆幅基本一致。联动螺栓与床头的联接高度误差可通过调整摇动盒高低予以消除。

六、润滑

床头部分使用润滑油润滑,通过油泵对各润滑部位进行润滑。润滑油添加量以刚好浸泡轴承为宜。

调坡机构摇动盒内注润滑油,其他活动部分使用润滑脂润滑。七、使用

1. 开机前人工转动大皮带轮,检查各运动件是否灵活无卡滞,各紧固螺丝是否松动。

2. 启动电机,观察电机转向(顺时针)是否正确,油泵供油是否正常。床头弹簧不宜过紧,应稍放松弹簧顶紧螺丝使尾杆在运动时有轻微的撞击声,此时再逐渐拧紧弹簧顶紧螺丝至响声消失即可,并将锁紧螺母锁紧。

3. 控制给矿量和给矿浓度,保证矿浆能沿床面有充分的流动性和能够分层为宜。一般选别时,粗砂给矿浓度为 12%~38%,细泥给矿浓度13%~20%。

4. 横向坡度和洗水量是影响摇床选矿质量的重要因素,它们和矿粒的横向运动有直接关系,直接影响到精矿质量和尾矿损失率,一般情况:给矿粒度大、浓度大、给矿量大,采用较大的坡度和洗水量。洗水量和横向坡度调节适宜时,水流分布均匀、不拉沟、不起砂堆,精矿带宽而薄,分带明显;若横向坡度过大,矿浆流速快、精矿带变窄; 若坡度过小,矿浆流速慢、精矿带分不清;洗水量过大,精矿带变窄、部分精矿跑人中矿,回收率低。

5. 停机前先停止给矿,待床面上的矿物选别完毕,停止冲洗水,然后停机。停机后,用水将床面清洗干净,以免杂质氧化结垢。

Order via Online Message