Shaking machine instruction manual

I. Overview

6-S Shaking Table belongs to gravity separation equipment, which is developed from plane chute.It is widely used in the re-election production process for its wide particle size, high sorting efficiency, intuitive working condition and easy operation and management.

6-S shaking table is mainly used for separating gold, tungsten, tantalum, iron, manganese, chromium, titanium, bismuth, lead and other non-ferrous, ferrous and rare precious metal minerals, and can also be used to sort other materials with sufficient specific gravity difference and suitable particle size composition.The use of shaking table beneficiation is stable and reliable, the distribution of ore zone is clear, and can get the concentrate and discard the tailings.

II. Working Principle

Shaking table sorting is realised under the effect of longitudinal reciprocating motion and transverse water flow on the bed surface, water flows transversely across a bed strip when forming water eddy in the groove, water eddy and longitudinal motion of the bed surface work together to make the ore sand layer loose and stratified according to specific gravity, different specific gravity of the ore particles, moving along the bed surface with different speeds, subject to the effect of transverse water flushing is also different, the formation of different specific gravity distribution of ore belt discharged, to achieve the purpose of sorting.

Structure of shaking table

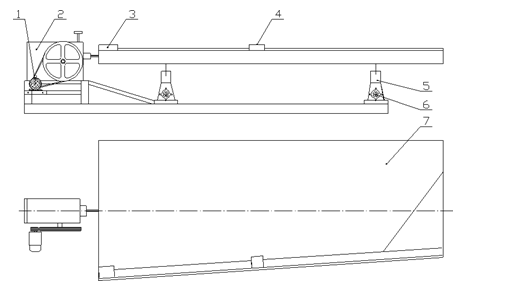

6-S shaking table consists of three parts: bed head (transmission mechanism), bed surface and bed foot (slope adjustment mechanism), as shown in Fig. 1.

1. bed head (transmission mechanism)

Shaking bed transmission mechanism adopts eccentric elbow plate type, connected with bed surface through linkage seat, so that the bed surface makes asymmetric movement along the longitudinal direction.

When rotating the stroke adjusting handwheel clockwise, the adjusting slider moves upward and the angle between the two elbow plates increases, thus the stroke decreases, on the contrary, rotating the adjusting handwheel counterclockwise increases the stroke.

Figure 1: 6-S shaking table structure

1. motor 2. bed head (drive mechanism) 3. feeder tank 4. wash water tank

5. bed foot (slope adjustment mechanism) 6. slope adjustment handwheel 7. bed surface

Fig. 2: 6-S Rocker Head Structure

1.Linkage seat 2.Reciprocating lever 3.Stroke adjusting screw 4.Movable elbow plate seat 5.Rocker bar

6. elbow plate 7. eccentric shaft 8. fixed elbow plate 9. spring 10. tailstock 11. tailstock

12. case 13. spring loaded bolt 14. large pulley 15. stroke adjustment handwheel

After adjusting the stroke, the spring adjusting bolts at the back of the transmission box must be adjusted accordingly so that the spring can be properly loosened and tightened to avoid damaging the parts due to over-loosening or over-tightening of the spring.

2. Slope adjustment mechanism

The slope adjusting mechanism of the shaking machine is composed of shaking support, adjusting seat, saddle seat and adjusting screw, etc. When rotating the adjusting handwheel, it will be adjusted by the adjusting screw. When rotating the adjusting handwheel, the adjusting seat rotates on the saddle seat through the screw, so as to change the lateral inclination of the bed surface.

The lateral inclination angle of the bed surface is changed.Clockwise rotation of the handwheel increases the tilt angle, counterclockwise rotation of the handwheel reduces the tilt angle.

3. Bed surface

The bed surface of shaking table is trapezoidal in shape with right angle, generally made of wood or glass fiber reinforced plastic wrapped with steel skeleton, and the working surface is formed by special wear-resistant layer of groove, and the groove is divided into straight and wave (single wave and double wave), and according to the different grain size of the minerals to be selected, there are coarse sand bed, medium sand bed, fine sand bed and fine mud bed.

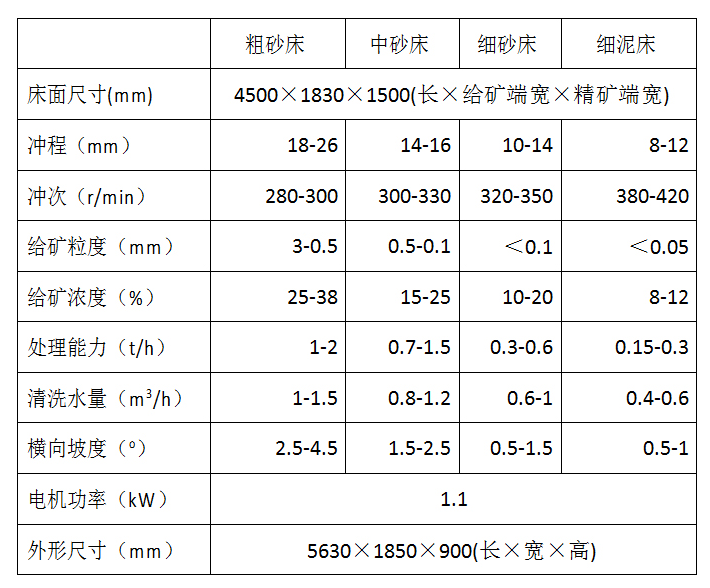

IV. Technical Parameters

V. Installation

The equipment shall be installed on a horizontal concrete foundation.

1. install the channel steel bracket on the foundation. 2. install the drive mechanism and slope adjustment mechanism;

2. Install the drive mechanism and the slope adjustment mechanism, set the slope adjustment handwheel in the direction of the sand (water) tank on the bed surface, and correct the two slope adjustment mechanisms to make the rotary centre line coincide with the centre line of the bed head.

3. Place the bed surface on the rocker plate, correct the contact position between the bed surface and the rocker plate, and then tighten the fixing bolts of the rocker box.

4. Connect the linkage bolts between the bed surface and the head, turn the big pulley to make the bed surface move longitudinally, observe and adjust the linkage bolts to make the front and back swing of the four rocking plates basically the same.The linkage bolt and the head of the bed can be eliminated by adjusting the height of the rocker box.

Sixth, lubrication

Head part of the use of lubricating oil lubrication, through the oil pump on the lubrication part of the lubrication.Lubricating oil to add just enough to soak the bearings as appropriate.

The lubricant is injected into the shaking box of the slope adjustment mechanism, and other movable parts are lubricated with grease.Use

1. manually rotate the big pulley before starting the machine, check whether the moving parts are flexible and free of stagnation, and whether the fastening screws are loosened.

2. Start the motor, observe whether the motor steering (clockwise) is correct, whether the oil pump oil supply is normal.The bed spring should not be too tight, should slightly relax the spring top screw so that the tail rod in the movement of a slight impact sound, and then gradually tighten the spring top screw to the disappearance of the sound can be, and lock the lock nut lock.

3. control the amount of feed and feed concentration, to ensure that the slurry can have sufficient mobility along the bed surface and can be layered as appropriate.

Enough stratification is appropriate.Generally speaking, the concentration of coarse sand is 12%-38%, and the concentration of fine mud is 13%-20%.

4. lateral slope and washing water is an important factor affecting the quality of shaking table ore dressing, they and the lateral movement of the ore particles have a direct relationship, directly affecting the quality of concentrates and tailings loss rate, the general situation: large particle size, concentration, large amount of ore feeding, using a larger slope and washing water.Wash water volume and lateral slope adjustment is appropriate, the water distribution is uniform, not pulling the ditch, not a sand heap, concentrate belt wide and thin, the band is obvious; if the lateral slope is too large, the slurry flow rate is fast, the concentrate band becomes narrower; if the slope is too small, the slurry flow rate is slow, the concentrate band can not be divided; wash water is too large, the concentrate band becomes narrower, part of the concentrate runners in the mine, the recovery rate is low.

5. Before stopping the machine, stop feeding the ore, wait for the minerals on the bed to be finished, stop washing water and stop the machine.After stopping the machine, use water to clean the bed surface, so as not to oxidise the impurities and scale.

Jianan Machinery--Professional Customised Jigger Machine

30 years focus on jigger source manufacturer